Brewing was the most important support industry of them all. Beer was needed in large quantities to keep the mill workers happy, especially in the early days when the hours were punitive and recreational opportunities limited.

Brewing was at one time a cottage industry. It was a commonplace domestic skill and people would no more have thought of buying beer than they would of buying bread, or apple pies or oatcakes. And as a domestic skill it was practised by women. Factory work was not compatible with these time consuming skills and they became specialised activities.

Inns and alehouses became the centres of brewing activity. Again in the early days it was an activity associated with women. 'Ale-wives' such as Eleanor Rummynge and Mother Louise were well known. Brewhouses operated on a small scale and most were also ale-houses.

Just as cotton weaving and spinning ceased to be done on a small scale and became a factory process, so brewing began to be carried out on a larger and larger scale. Specialisation, mass production and improved communications via road and rail heralded the advent of the major brewers.

By Alan Duckworth

Traditionally a Cooper is someone who makes wooden barrels which are held together with metal hoops and have flat ends or heads. They were mainly used for Beer, Whisky and Wine and so designed to keep moisture out, thus preserving the product.

The place in which casks are made is referred to as a Cooperage.

A brewery cooper was an immensely skilled craftsman; he had to work to the nearest pint. Brewery barrels were the only barrels to have the insides shaved completely smooth to prevent bacteria forming and ruining the beer. The Foreman Cooper used to run a silk handkerchief around the inside of the barrel to test it and if the handkerchief caught, then the barrel was sent back to the Cooper to be shaved again.

In a brewery the largest barrel held 54 gallons and was called a Hogshead, 36 gallons was a barrel, 18 gallons was a Kilderkin, and 9 gallons was a Firkin.

There was a lot of secrecy about the Cooper because nothing was written down. A Cooper passed his trade onto his son; this rule was strictly adhered to by the Lancashire Coopers Society.

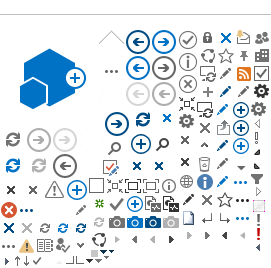

When an apprentice Cooper had served for 5 years he had to go through a barbarous ceremony called “The Trusso".

Blackburn Times Friday June 14th 1957.

The Apprentice is my Cousin Ken Mawson

© Blackburn Times

First the apprentice had to make his own barrel and then it was heated for an hour and a half over a brazier. He then had to climb into the barrel whilst five coopers pounded away on the outside hoops with hammers. Every now and then water was swished into the barrel whilst soot and wood shavings where added along with a pint of beer.

The apprentice was allowed out of the barrel and was immediately given his cards (sacked) by the Foreman. He then applied to the Head Brewer to be re-engaged as a Cooper.

Coopering declined in the 1960/1970s when breweries started using metal barrels. The only remaining Cooper making wooden Barrels today is in West Yorkshire. He has taken on an apprentice, so the tradition, which dates back to Biblical times, could carry on for a few more years. In Scotland there about 200 Coopers thanks mainly to the whisky trade.

Researched and written by Jeffrey Booth Library Volunteer.